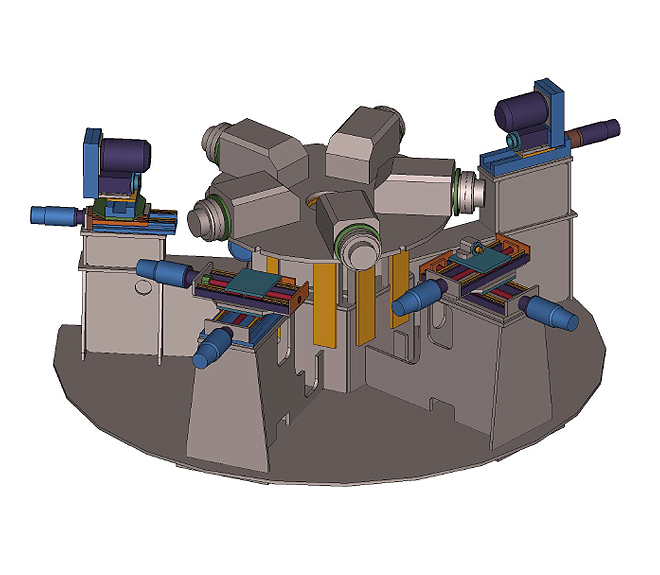

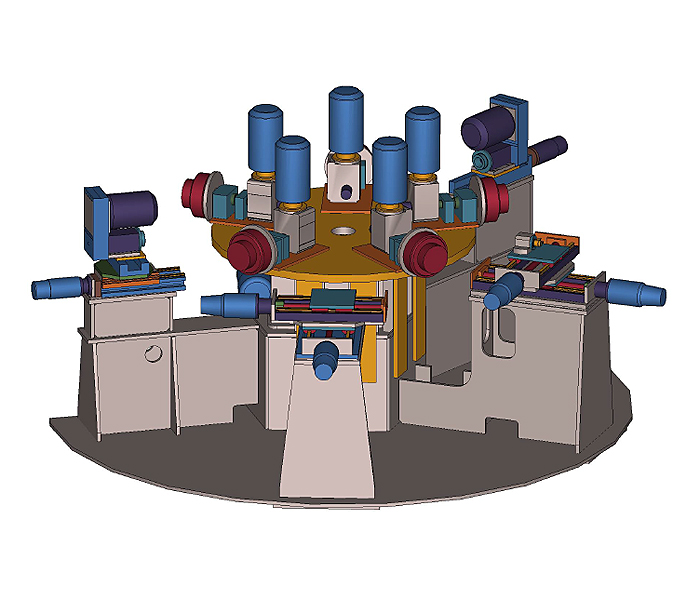

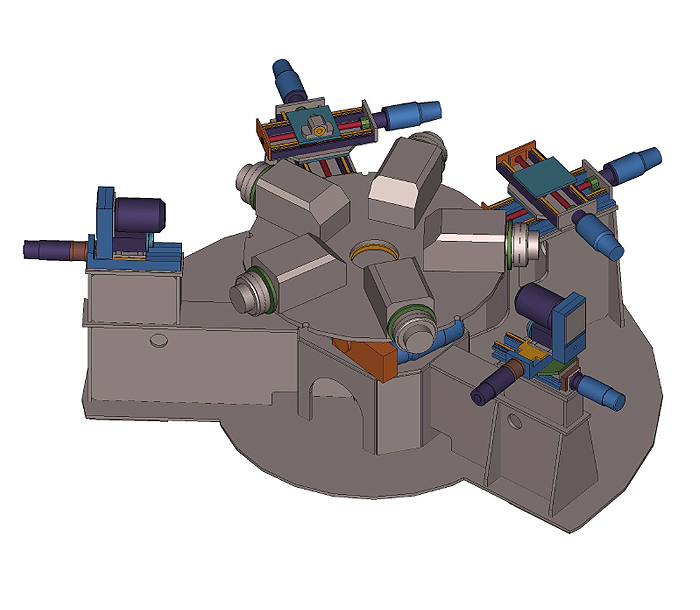

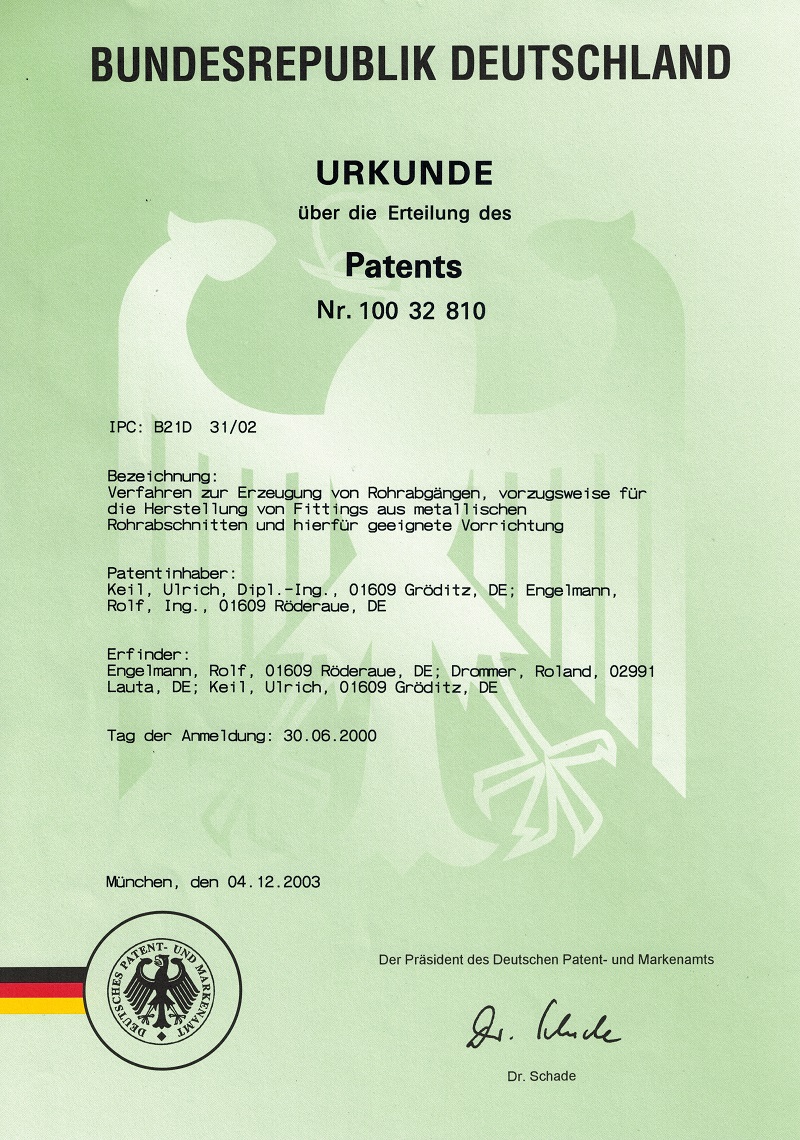

Extrusion machine

Die Aushalsmaschine ist zur Herstellung von T-Stücken aus zugeschnittenen Rohrmaterial konzipiert. Es können standardmäßig Rohre bis DN 54 1:1 und reduziert ausgehalst werden. Größere Abmessungen sind auf Anfrage möglich. In vier Arbeitsschritten, die zueinander parallel laufen, wird die zylindrische Kontur in die Mantelfläche eingearbeitet.

Die Arbeitsschritte sind:

Die Arbeitsschritte sind:

1. Entnahme und Einlegen des zu bearbeitenden Werkstückes

2. Einbringen eines Langloches für das Umformwerkzeug

2. Einbringen eines Langloches für das Umformwerkzeug

3. Erste Stufe der Umformung

4. Zweite Stufe der Umformung

4. Zweite Stufe der Umformung

5. Planbearbeitung der ausgehalsten Kontur

Die Werkstücke werden während der Bearbeitungsschritte im Spannfutter ohne Umspannung in den einzelnen Bearbeitungsstationen gehalten. Die Maschine ist mit einer leistungsfähigen SPS ausgestattet. Über eine visualisierte Oberfläche eines Industrie-PC’s, der mit der SPS kommuniziert, erfolgt die Bedienung der Maschine. Für die einzeln programmseitig hinterlegten Werkstücksortimente lassen sich die geometrischen Daten und Parameter laden und verändern. Somit ist es möglich, bei veränderten Toleranzen der Halbzeuge Anpassungen vorzunehmen. Das Betreiben der Maschine ist in einer 2-Maschinen-Bedienung möglich. Die Station 1 (Entnehmen und Einlegen der Werkstücke) ist automatisierbar.

Technische Daten

Medienanschlüsse:

- Elt: 400V / 50Hz

- Anschlussleistung: ca. 38 kW

- Druckluft: mind. 6 bar

Bearbeitungsbereich der Werkstücke:

- DN 10 bis 54 mm (auch größer)

- Länge bis ca. 200 mm

- Wandstärke max. 4mm bei großen DN

- Werkstoffe aus Stahl, rostfrei, Messing, Kupfer

Abmessungen:

L x B x H: 5700x 3800x3000 mm

Incl. Schaltschrank und Bedien- und Wartungsfläche