Collaring technology

The company ATG Automations-Technik Gröditz GmbH & Co. KG has developed a new process for the collaring of metallic tubes and tubular parts. Collars are needed to create outlets on pipes and to produce T-pieces.

Through simple, cost-effective collaring tools and by means of an incremental process, the collar geometry is formed on the respective length of the pipe. Due to the cyclic forming, the force input in the metal can be individually adjusted, which results in gentle material forming and low heat input. This process also enables true 1:1 collaring, for special applications collars larger than the original pipe diameter.

Thanks to the intuitive program interface and the configurable software, the user is able to insert the desired collar after a short training period.

Due to waiver of lubricants and slip additives during the collaring process, the workpieces can be further processed without intermediate steps, which saves costs and protects the environment. It can also be used to ensure food safety, as no substances harmful to humans are rolled into the material during the process.

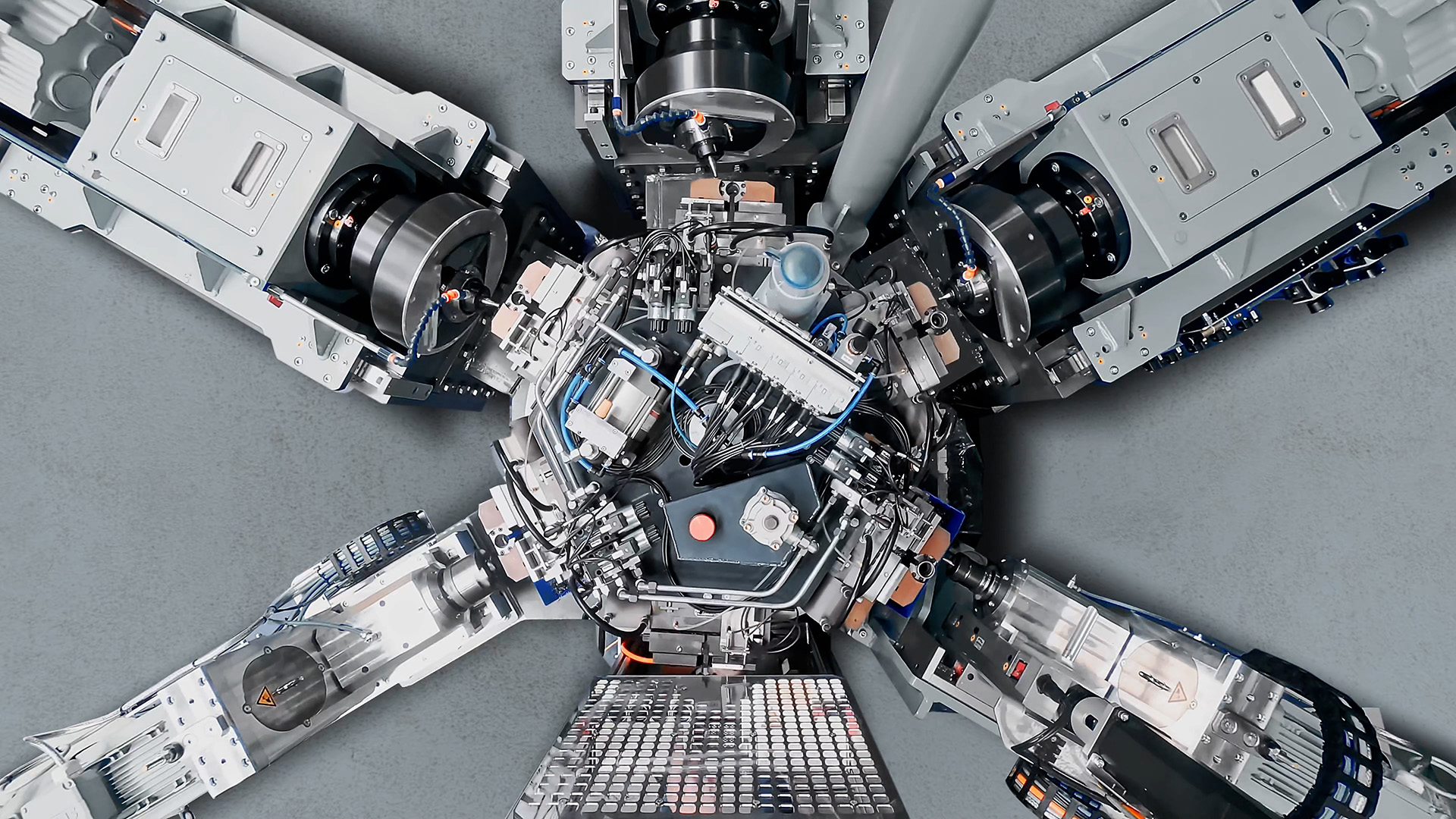

Whether a complete collar cell or a single collaring module, you have the choice with this innovative manufacturing process.