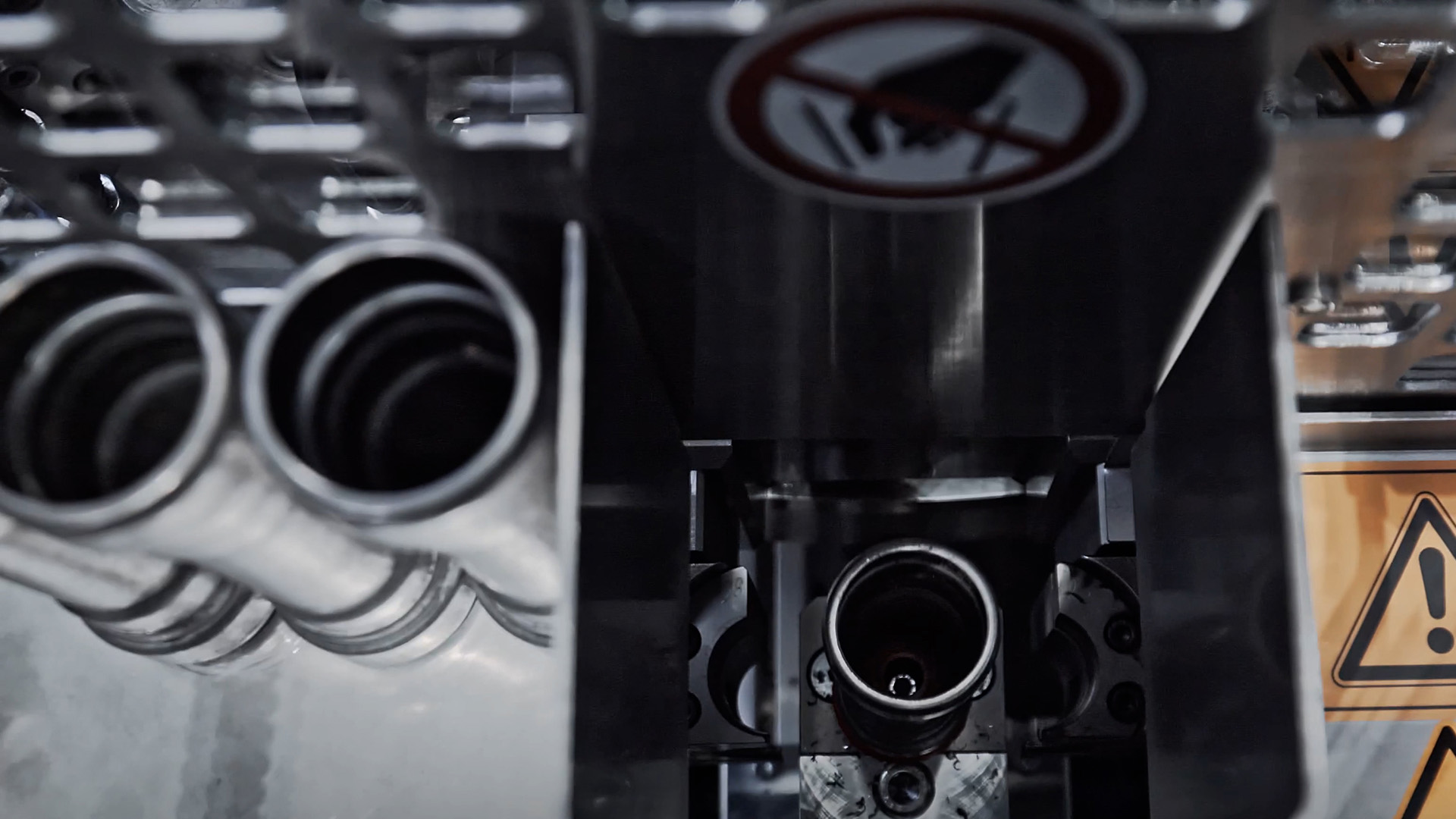

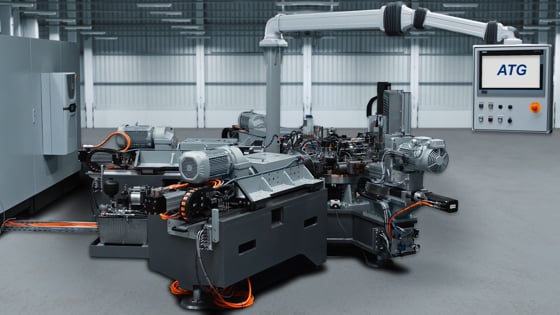

Collaring machine

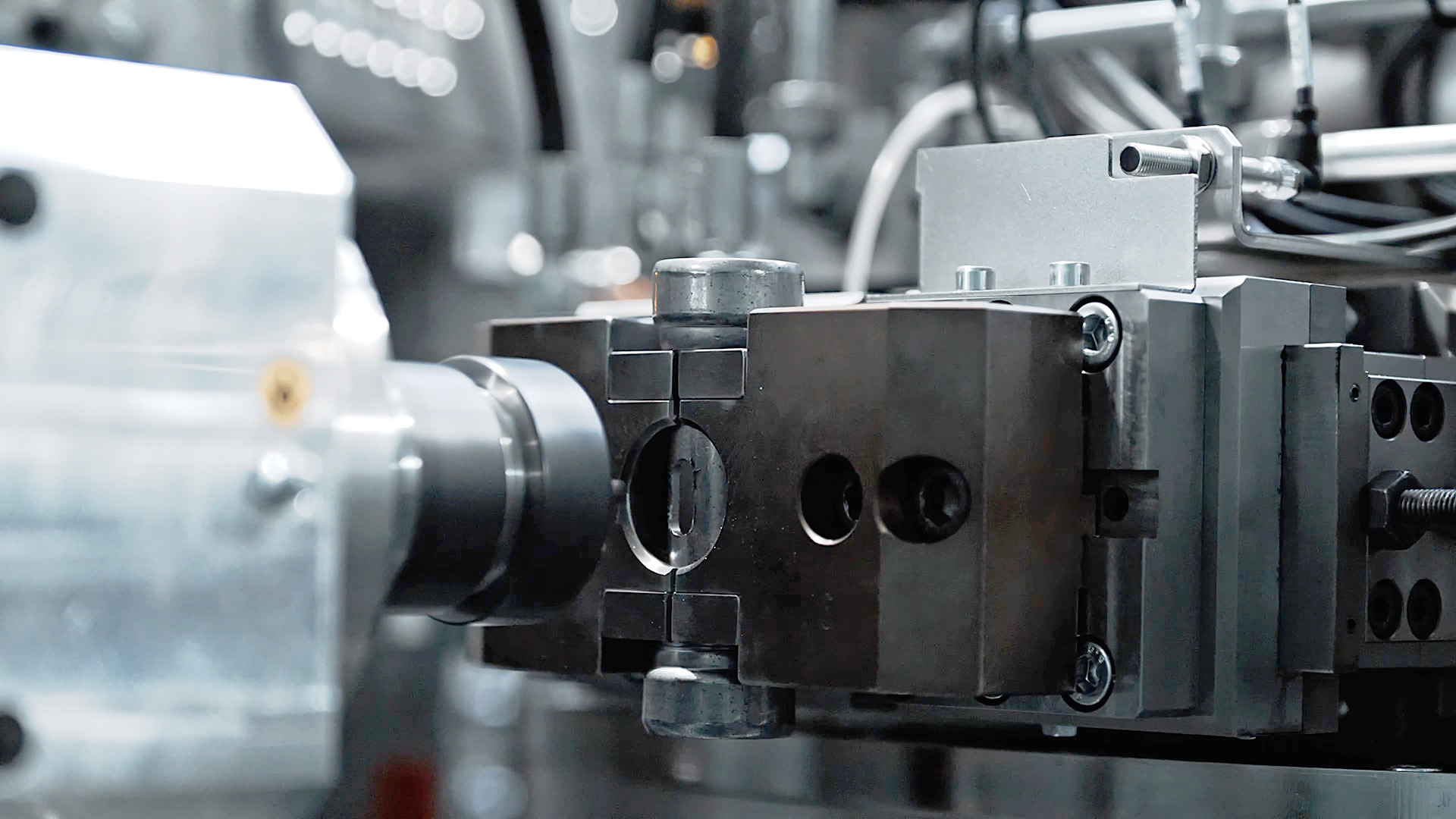

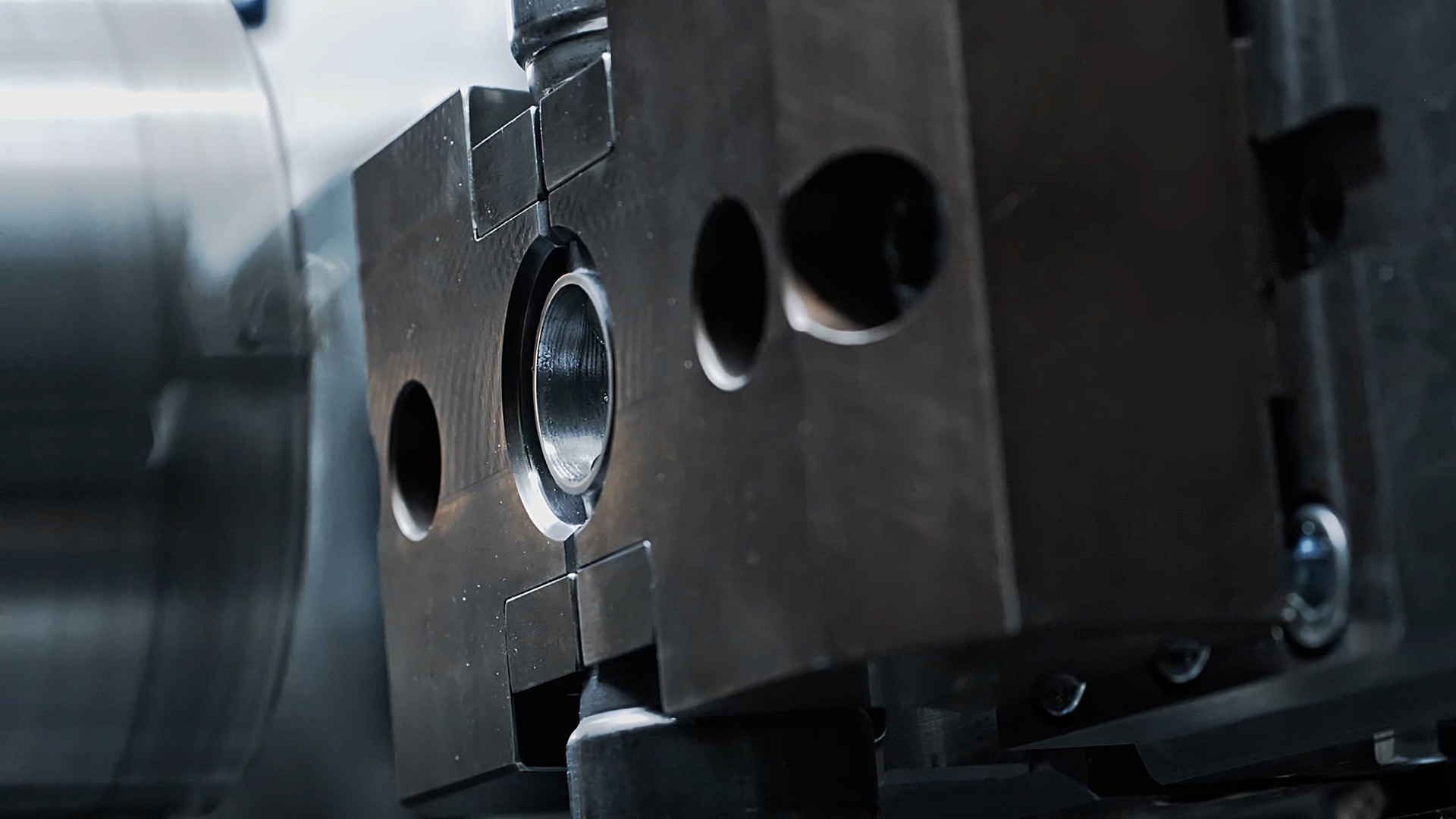

Collaring is a mechanical process for the seamless attachment of outlets to pipes for the production of T-pieces or branches in pipeline construction. The fully automatic collaring machine developed by ATG is designed for the large-scale production of blanks for T-pieces. This system combines all work steps, from insertion into the collaring machine, the milling of the pre hole, the actual collaring and the production of the weld seam preparation.

The ATG collaring machine is particularly characterised by the following features:

The ATG collaring machine is particularly characterised by the following features:

- Easy handling and high variability thanks to clear, parameterisable software

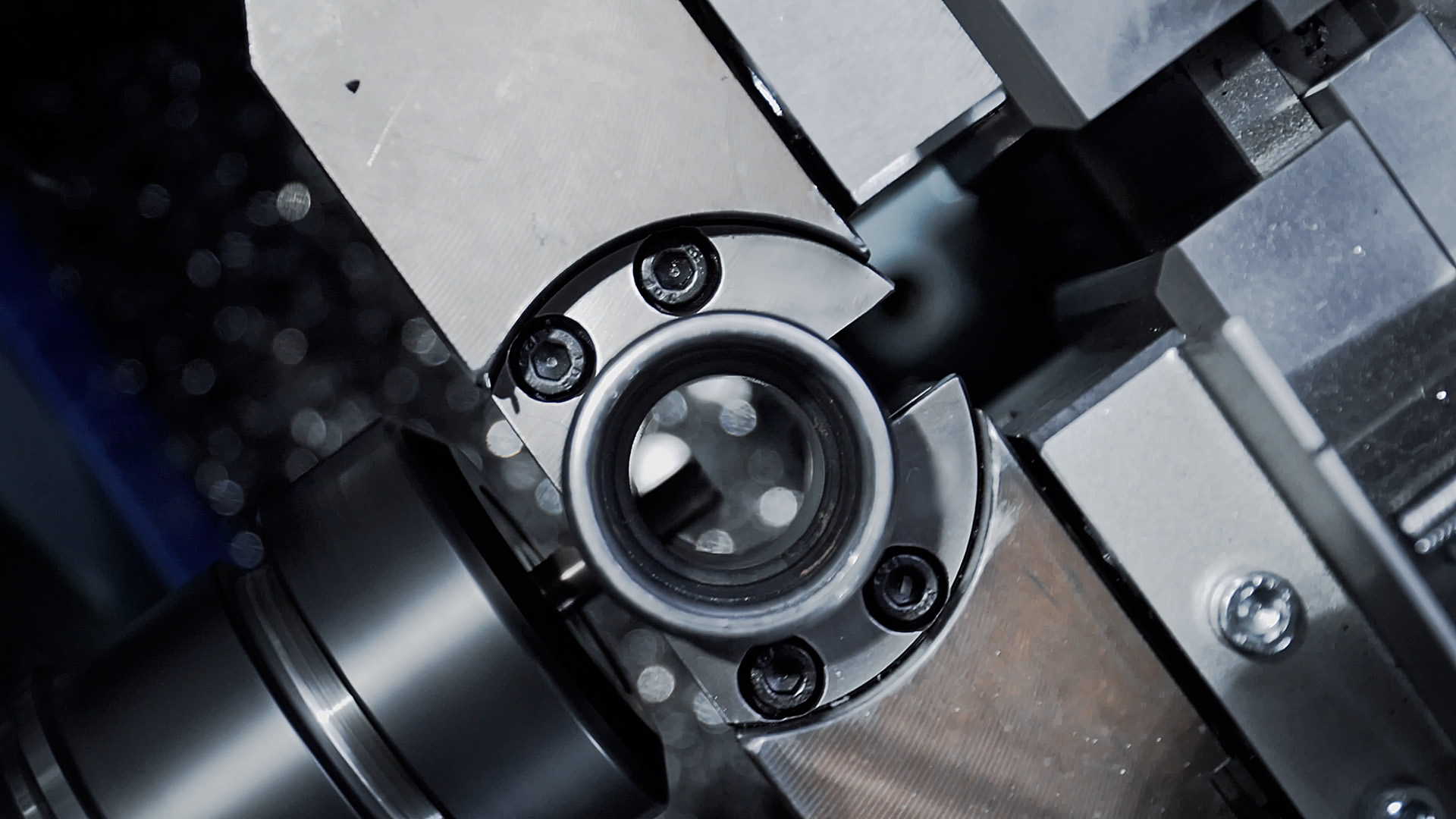

- Low tool costs thanks to simple rotationally symmetrical collaring tools

- Environmentally friendly, as there is no need for coolants and lubricants during collaring

- Particularly gentle on the material thanks to incremental expansion and low heat input

- High productivity with consistent quality of the outlet geometry

- Real 1:1 collars is possible thanks to the special rolling process

Please accept the cookies for external media in order to play this video.

Change cookie settings