Production automation

In today's world, there is increasing pressure on companies to automate parts or even the entire production line. Simple, repetitive activities in particular can be carried out more efficiently and cost-effectively by robots. Even more complex tasks for industrial robots are no longer a unusual challenge today. Especially in combination with camera systems, production can be automated selectively or across machines. Whether it's removing parts from a box or visually inspecting components - both can be done quickly, efficiently and cost-effectively.

Projects of implemented production automations

- 3D bin picking systems for loading production machines

- Intelligent sorting of components using RFID technology

- Dosing, mixing and weighing of powdered substances

- Quality control using 2D evaluation technology

Please accept the cookies for external media in order to play this video.

Change cookie settings

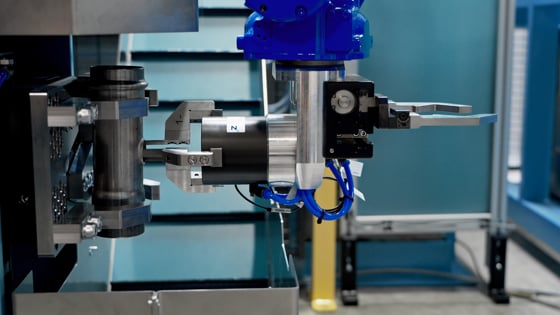

3D bin-picking system

- Fully automatic removal of the blanks from the box

- clear software and simple program changes

- Innovative gripper solutions adapted to the respective blanks

- High cycle times adapted to the machine to be fed

- human intervention no longer necessary for repetitive work

Please accept the cookies for external media in order to play this video.

Change cookie settings

By automating manufacturing processes, costs can be reduced, errors minimized and production times shortened. All this increases your competitiveness.