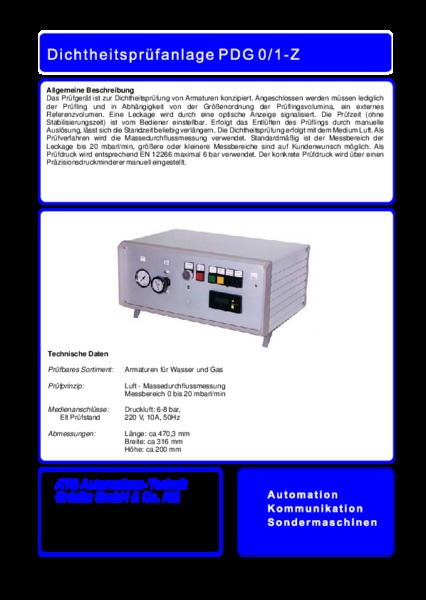

Leak test unit PDG 0/1-Z

Das Prüfgerät ist zur Dichtheitsprüfung von Armaturen konzipiert. Angeschlossen werden müssen lediglich der Prüfling und in Abhängigkeit von der Größenordnung der Prüflingsvolumina, ein externes Referenzvolumen. Eine Leckage wird durch eine optische Anzeige signalisiert. Die Prüfzeit (ohne Stabilisierungszeit) ist vom Bediener einstellbar. Erfolgt das Entlüften des Prüflings durch manuelle Auslösung, lässt sich die Standzeit beliebig verlängern.

Die Dichtheitsprüfung erfolgt mit dem Medium Luft.Als Prüfverfahren wird die Massedurchflussmessung verwendet. Standardmäßig ist der Messbereich der Leckage bis 20 mbarl/min, größere oder kleinere Messbereiche sind auf Kundenwunsch möglich. Als Prüfdruck wird entsprechend EN 12266 maximal 6 bar verwendet. Der konkrete Prüfdruck wird über einen Präzisionsdruckminderer manuell eingestellt.

Technische Daten

Prüfbares Sortiment:

Armaturen für Wasser und Gas

Armaturen für Wasser und Gas

Prüfprinzip:

- Luft - Massedurchflussmessung

- Messbereich 0 bis 20 mbarl/min

Medienanschlüsse:

- Druckluft: 6-8 bar

- Elt Prüfstand: 220 V, 10A, 50Hz

Abmessungen:

Länge: ca 470,3 mm

Breite: ca 316 mm

Höhe: ca 200 mm

Breite: ca 316 mm

Höhe: ca 200 mm