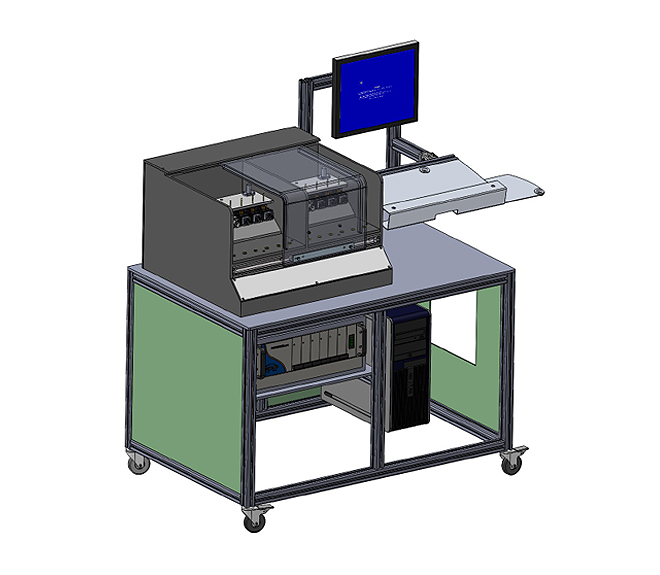

High potential test stand

Der Prüfstand dient zur Isolationsmessung und Spannungsfestigkeitsprüfung von Schaltermodulen

(nachfolgend „Prüflinge“ genannt). Dazu besitzt der Prüfstand eine steuerbare Hochspannungsquelle

(nachfolgend „HV-Gerät“ genannt) und eine Doppelprüfkammer in dem jeweils 6 Prüflinge gleichzeitig wechselseitig geprüft werden können.

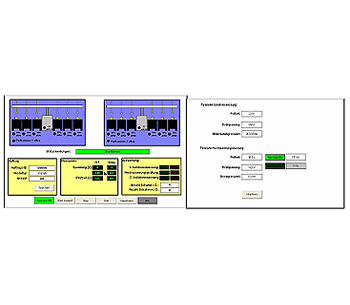

Nach dem Start der Prüfung werden die Prüflinge zunächst gemeinsam, nach den festgelegten Prüfungen (1. erste Isolationsmessung, 2. Spannungsfestigkeitsprüfung und 3. zweite Isolationsmessung) mit den eingestellten Prüfparametern getestet. Tritt bei der Prüfung ein Fehler (Isolationswiderstand zu klein oder Strom zu hoch) auf, wird jeder der 6 Prüflinge getrennt von den anderen einem Kurztest unterzogen, um so die Fehlerquelle auszumachen. Während des Prüfvorgangs stehen die Steuerung und das HV-Gerät in ständiger Kommunikation und die aktuellen Werte von Spannung, Strom, Widerstand und Prüfzeit werden ständig angezeigt. Das Ergebnis der Prüfung wird auf dem Bildschirm als Klartextmeldung ausgegeben und gleichzeitig für jeden Prüfling „in Ordnung“ oder „nicht in Ordnung“ visuell dargestellt.

Die Eingabe der Prüfparameter wird kundenspezifisch von fest einprogrammierten Werten über manuell veränderbare bis zur Typ-spezifischen Prüfdatenbank realisiert. Ebenso erfolgt die Auswertung der Prüfergebnisse kundenspezifisch von einfacher Signalisierung des Prüfergebnisses über Signierung bis zu einer Datenbank der Prüfergebnisse mit automatischer Zertifikaterstellung.

(nachfolgend „Prüflinge“ genannt). Dazu besitzt der Prüfstand eine steuerbare Hochspannungsquelle

(nachfolgend „HV-Gerät“ genannt) und eine Doppelprüfkammer in dem jeweils 6 Prüflinge gleichzeitig wechselseitig geprüft werden können.

Nach dem Start der Prüfung werden die Prüflinge zunächst gemeinsam, nach den festgelegten Prüfungen (1. erste Isolationsmessung, 2. Spannungsfestigkeitsprüfung und 3. zweite Isolationsmessung) mit den eingestellten Prüfparametern getestet. Tritt bei der Prüfung ein Fehler (Isolationswiderstand zu klein oder Strom zu hoch) auf, wird jeder der 6 Prüflinge getrennt von den anderen einem Kurztest unterzogen, um so die Fehlerquelle auszumachen. Während des Prüfvorgangs stehen die Steuerung und das HV-Gerät in ständiger Kommunikation und die aktuellen Werte von Spannung, Strom, Widerstand und Prüfzeit werden ständig angezeigt. Das Ergebnis der Prüfung wird auf dem Bildschirm als Klartextmeldung ausgegeben und gleichzeitig für jeden Prüfling „in Ordnung“ oder „nicht in Ordnung“ visuell dargestellt.

Die Eingabe der Prüfparameter wird kundenspezifisch von fest einprogrammierten Werten über manuell veränderbare bis zur Typ-spezifischen Prüfdatenbank realisiert. Ebenso erfolgt die Auswertung der Prüfergebnisse kundenspezifisch von einfacher Signalisierung des Prüfergebnisses über Signierung bis zu einer Datenbank der Prüfergebnisse mit automatischer Zertifikaterstellung.

Technische Daten

Prüfbares Sortiment: Schaltermodule

Prüfprinzip: Isolationsmessung; Festigkeitsprüfung

Mechanische Daten

Prüfprinzip: Isolationsmessung; Festigkeitsprüfung

Mechanische Daten

- Abmessungen (L x B x H): mm 1200x795x1300

- Platzbedarf (L x B): mm 1500 x 1000

- Gewicht: ca. 80 kg

Elektrische Daten

- Betriebsspannung: 230 V AC

- Steuerspannung: 24 V DC

Druckluft-Versorgung

- Luftdruck: 6 bar

- Luft-Qualität: Reinheitsgrad 3