Test stand for manifold bar

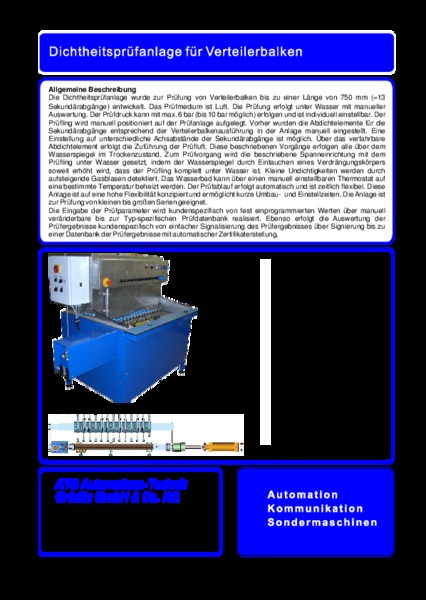

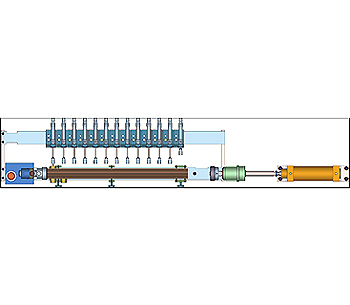

Die Dichtheitsprüfanlage wurde zur Prüfung von Verteilerbalken bis zu einer Länge von 750 mm (= 13 Sekundärabgänge) entwickelt.Das Prüfmedium ist Luft. Die Prüfung erfolgt unter Wasser mit manueller Auswertung. Der Prüfdruck kann mit max. 6 bar (bis 10 bar möglich) erfolgen und ist individuell einstellbar. Der Prüfling wird manuell positioniert auf der Prüfanlage aufgelegt. Vorher wurden die Abdichtelemente für die Sekundärabgänge entsprechend der Verteilerbalkenausführung in der Anlage manuell eingestellt. Eine Einstellung auf unterschiedliche Achsabstände der Sekundärabgänge ist möglich.

Über das verfahrbare Abdichtelement erfolgt die Zuführung der Prüfluft. Diese beschriebenen Vorgänge erfolgen alle über dem Wasserspiegel im Trockenzustand. Zum Prüfvorgang wird die beschriebene Spanneinrichtung mit dem Prüfling unter Wasser gesetzt, indem der Wasserspiegel durch Eintauchen eines Verdrängungskörpers soweit erhöht wird, dass der Prüfling komplett unter Wasser ist. Kleine Undichtigkeiten werden durch aufsteigende Gasblasen detektiert. Das Wasserbad kann über einen manuell einstellbaren Thermostat auf eine bestimmte Temperatur beheizt werden. Der Prüfablauf erfolgt automatisch und ist zeitlich flexibel. Diese Anlage ist auf eine hohe Flexibilität konzipiert und ermöglicht kurze Umbau- und Einstellzeiten. Die Anlage ist zur Prüfung von kleinen bis großen Serien geeignet.

Die Eingabe der Prüfparameter wird kundenspezifisch von fest einprogrammierten Werten über manuell veränderbare bis zur Typ-spezifischen Prüfdatenbank realisiert. Ebenso erfolgt die Auswertung der Prüfergebnisse kundenspezifisch von einfacher Signalisierung des Prüfergebnisses über Signierung bis zu einer Datenbank der Prüfergebnisse mit automatischer Zertifikaterstellung.

Über das verfahrbare Abdichtelement erfolgt die Zuführung der Prüfluft. Diese beschriebenen Vorgänge erfolgen alle über dem Wasserspiegel im Trockenzustand. Zum Prüfvorgang wird die beschriebene Spanneinrichtung mit dem Prüfling unter Wasser gesetzt, indem der Wasserspiegel durch Eintauchen eines Verdrängungskörpers soweit erhöht wird, dass der Prüfling komplett unter Wasser ist. Kleine Undichtigkeiten werden durch aufsteigende Gasblasen detektiert. Das Wasserbad kann über einen manuell einstellbaren Thermostat auf eine bestimmte Temperatur beheizt werden. Der Prüfablauf erfolgt automatisch und ist zeitlich flexibel. Diese Anlage ist auf eine hohe Flexibilität konzipiert und ermöglicht kurze Umbau- und Einstellzeiten. Die Anlage ist zur Prüfung von kleinen bis großen Serien geeignet.

Die Eingabe der Prüfparameter wird kundenspezifisch von fest einprogrammierten Werten über manuell veränderbare bis zur Typ-spezifischen Prüfdatenbank realisiert. Ebenso erfolgt die Auswertung der Prüfergebnisse kundenspezifisch von einfacher Signalisierung des Prüfergebnisses über Signierung bis zu einer Datenbank der Prüfergebnisse mit automatischer Zertifikaterstellung.

Techniche Daten

Prüfbares Sortiment: Verteilerbalken bis 750 mm

Prüfverfahren: "Luft unter Wasser" (Dichtheit)

Prüfverfahren: BF und BO nach DIN 3230 Teil 3

Prüfverfahren: BF und BO nach DIN 3230 Teil 3

Prüfzeit: einstellbar, ca. 1 min

Medienanschlüsse:

Medienanschlüsse:

- Elt: 230V/10A/50Hz

- Druckluft: 4-6 bar

Abmessungen:

Länge: ca. 1800 mm

Breite: ca. 1030 mm

Höhe: ca. 2010 mm

Inhalt des Wasserbeckens: ca. 150 l

Länge: ca. 1800 mm

Breite: ca. 1030 mm

Höhe: ca. 2010 mm

Inhalt des Wasserbeckens: ca. 150 l