Leak test unit PDA 3/4-50

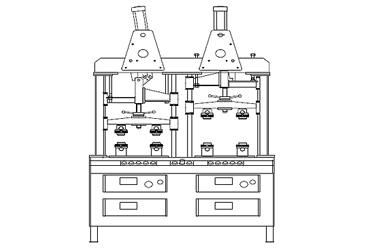

Die Dichtheitsprüfanlage PDA3/4-50 wurde zur Prüfung von Wasserarmaturen und Fittings mit dem Medium Luft entwickelt. Die Prüflinge bleiben damit trocken und können unmittelbar nach der Prüfung verpackt werden. Durch entsprechende Ausführung der Messtechnik und den wechselbaren Prüflingsaufnahmen kann der Prüfstand vielen geometrischen Formen von zu prüfenden Körpern angepasst werden. Die Anlage ist hinsichtlich seiner Prüfprogramme zur Prüfung des Gehäuses und auch des Ventilsitzes ausgelegt. Es wird mit einem Prüfdruck von 3 bar, bzw. 50 mbar für die Funktionsprüfung von Rückflussverhinderern gearbeitet. Das Einlegen und Entnehmen der Prüflinge erfolgt manuell, der Prüfablauf hingegen automatisch.

Die beiden Doppelspannstellen sind mit einem Kniehebelsystem ausgestattet und arbeiten unabhängig voneinander. Geprüft werden können kleine, mittlere, wie auch große Serien. Die Eingabe der Prüfparameter wird kundenspezifisch von fest einprogrammierten Werten über manuell veränderbare bis zur Typ-spezifischen Prüfdatenbank realisiert. Ebenso erfolgt die Auswertung der Prüfergebnisse kundenspezifisch von einfacher Signalisierung des Prüfergebnisses über Signierung bis zu einer Datenbank der Prüfergebnisse mit automatischer Zertifikaterstellung.

Die beiden Doppelspannstellen sind mit einem Kniehebelsystem ausgestattet und arbeiten unabhängig voneinander. Geprüft werden können kleine, mittlere, wie auch große Serien. Die Eingabe der Prüfparameter wird kundenspezifisch von fest einprogrammierten Werten über manuell veränderbare bis zur Typ-spezifischen Prüfdatenbank realisiert. Ebenso erfolgt die Auswertung der Prüfergebnisse kundenspezifisch von einfacher Signalisierung des Prüfergebnisses über Signierung bis zu einer Datenbank der Prüfergebnisse mit automatischer Zertifikaterstellung.

Technische Daten

Prüfbares Sortiment:

Absperrhähne, Kugelhähne, Rückflussverhinderer,

Fittings bis zur Nennweite 2"

Prüfprinzip: Medium Luft, Differenzdruckverfahren

Prüfverfahren: BF unf BO nach DIN 3230 Teil 3

Prüfschärfe: abhängig von Prüflingsvolumen und Prüfzeit, z.B. 1ml/min bei Absperrhähnen 1/2”

Medienanschlüsse:

Medienanschlüsse:

- Elt: 230V / 10A / 50Hzö,

- Druckluft: 6-10 bar

Abmessungen:

L x B x H: 1400 mm x 800 mm x 2300 mm