Leak detector PDAT 1/2-SK for float balls

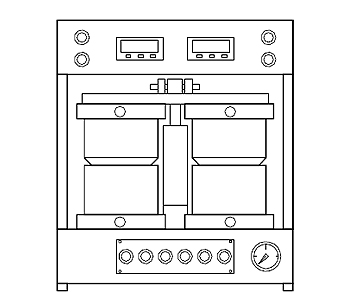

Das Dichtheitsprüfgerät PDAT 1/2-SK wurde zur Prüfung von Schwimmerkugeln mit dem Medium Luft entwickelt. Damit wurde die Prüfgenauigkeit gegenüber dem herkömmlichen Verfahren (Tauchen in heißem Wasser) verbessert. Zugleich wird durch die "trockene" Prüfung die Oberflächenqualität der Kugeln nicht beeinträchtigt und eine Trocknung entfällt. Das Gerät ist als Tischgerät ausgeführt und besitzt zwei speziell an die Kontur der Prüflinge angepasste Prüfkammern. Die Prüfkammern selbst sind leicht austauschbar, wodurch ein breites Prüflingssortiment möglich ist. Geeignet ist das Prüfgerät für kleine bis große Serien.

Die Eingabe der Prüfparameter wird kundenspezifisch von fest einprogrammierten Werten über manuell veränderbare bis zur Typ-spezifischen Prüfdatenbank realisiert. Ebenso erfolgt die Auswertung der Prüfergebnisse kundenspezifisch von einfacher Signalisierung des Prüfergebnisses über Signierung bis zu einer Datenbank der Prüfergebnisse mit automatischer Zertifikaterstellung.

Die Eingabe der Prüfparameter wird kundenspezifisch von fest einprogrammierten Werten über manuell veränderbare bis zur Typ-spezifischen Prüfdatenbank realisiert. Ebenso erfolgt die Auswertung der Prüfergebnisse kundenspezifisch von einfacher Signalisierung des Prüfergebnisses über Signierung bis zu einer Datenbank der Prüfergebnisse mit automatischer Zertifikaterstellung.

Technische Daten

Prüfbares Sortiment: Schwimmerkugeln oder ähnliche geschlossene Hohlkörper, bis etwa 1000 ml Volumen

Prüfverfahren: Differenzdruckverfahren mit dem Medium Luft

Prüfzeit: ca. 35 sec für 2 Prüflinge (abhängig vom Volumen und dem eingestellten Grenzwert für eine Leckage)

Medienanschlüsse:

Prüfverfahren: Differenzdruckverfahren mit dem Medium Luft

Prüfzeit: ca. 35 sec für 2 Prüflinge (abhängig vom Volumen und dem eingestellten Grenzwert für eine Leckage)

Medienanschlüsse:

- Elt: 230V/10A/50Hz

- Druckluft: 6-8 bar

Abmessungen:

Breit: 480 mm

Tiefe: 493 mm

Höhe: 550 mm

Tiefe: 493 mm

Höhe: 550 mm