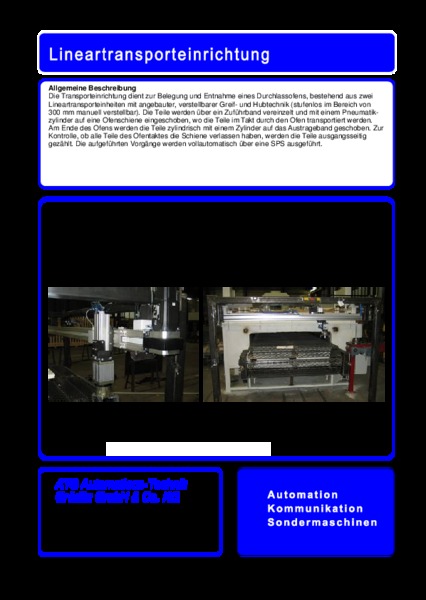

Linear conveyor module

Die Transporteinrichtung dient zur Belegung und Entnahme eines Durchlassofens, bestehend aus zwei Lineartransporteinheiten mit angebauter, verstellbarer Greif- und Hubtechnik (stufenlos im Bereich von300 mm manuell verstellbar). Die Teile werden über ein Zuführband vereinzelt und mit einem Pneumatikzylinder auf eine Ofenschiene eingeschoben, wo die Teile im Takt durch den Ofen transportiert werden. Am Ende des Ofens werden die Teile zylindrisch mit einem Zylinder auf das Austrageband geschoben. Zur Kontrolle, ob alle Teile des Ofentaktes die Schiene verlassen haben, werden die Teile ausgangsseitig gezählt. Die aufgeführten Vorgänge werden vollautomatisch über eine SPS ausgeführt.

Technische Daten

- Verfahrweg der Lineareinheit: ca. 1800 mm

- Verfahrgeschwindigkeit: ca. 0,5 m/s

- Vertikaler Hub des Greifers: ca. 30 mm

- Anzahl der anzufahrenden Pos.: 8

- aktzeit/Positionierzyklus/Teil: 50 s

- max. Handlingmasse (bei 6 bar): 15 kg

- Druckluft: mind. 6 bar trocken

- Elt-Anschluss: AC 400 V