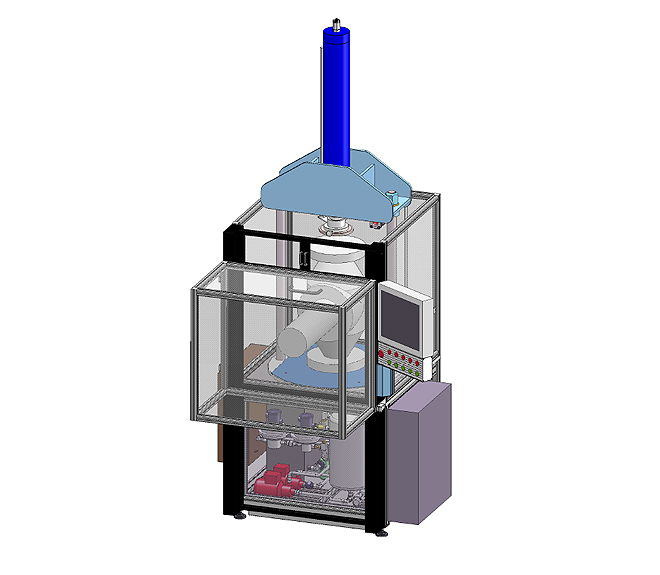

Universal test stand up to 1000 bar

Die Prüfmaschine ist bestimmt zum Prüfen von geraden Armaturen auf Festigkeit und Dichtheit gemäß DIN EN ISO 12266-1 im Abmessungsbereich von DN 15 bis DN 150.

Der geforderte Prüfdruck (Wassergemisch) für die Festigkeitsprüfung P10 und Dichtheit des tragenden Gehäuses P11 beträgt max. 1000 bar und ist für die niedrigen Druckstufen (PN 16 bis PN 160, CL 150 bis CL 2500) entsprechend im Prüfprogramm hinterlegt angepasst. Die Erzeugung des Wasserdrucks erfolgt mit zwei Hochdruckpumpen auf dem Prinzip der pneumatisch-hydraulischen Druckübersetzung. Durch die Regelung des Pneumatikdrucks wird der Wasserdruck geregelt. Für die Sitzdichtheit P12 ist ein max. Luftdruck von 6 bar mit der entsprechenden Anpassung an die niedrigeren Nenndrücke erforderlich. Dieser Druck wird direkt dem Druckluftnetz entnommen. Das Prüfwasser wird vom Wasserbehälter über einen Filter mit einer Pumpe in den Füllbehälter befördert. Anschließend wird der Prüfling unter Vakuum stehend mit dem Wasser gefüllt. Damit wird sichergestellt, dass sich keine Luft im Prüfling befindet. Nach dem Füllen wird der Prüfdruck erzeugt. Der Druckabfall während der Prüfung wird mittels Drucksensor ausgewertet und entsprechend signalisiert.

Die Eingabe der Prüfparameter wird kundenspezifisch von fest einprogrammierten Werten über manuell veränderbare bis zur Typ-spezifischen Prüfdatenbank realisiert. Ebenso erfolgt die Auswertung der Prüfergebnisse kundenspezifisch von einfacher Signalisierung des Prüfergebnisses über Signierung bis zu einer Datenbank der Prüfergebnisse mit automatischer Zertifikaterstellung.

Technische Daten

Prüfbares Sortiment: gerade Armaturen

Prüfprinzip: Wasser

Prüfprinzip: Wasser

Mechanische Daten

- Abmessung (L x B x H): mm 1470x1160x330

- Platzbedarf (L x B): mm 2000 x 150

- Gewicht:800 kg

Elektrische Daten

- Betriebsspannung: 400 V AC

- Steuerspannung: 24 V DC

Druckluft-Versorgung

- Luftdruck: 6 bar

- Luft-Qualität: Reinheitsgrad 3

Ölmenge (Hydraulik): 26 l

Ölmenge (Pneumatik) im Öler: max. 45 cm²

Wassermenge: 50 l

Ölmenge (Pneumatik) im Öler: max. 45 cm²

Wassermenge: 50 l